In today’s fast-paced warehouse and distribution environments, storage is no longer just about shelving products in the available space. Companies are under constant pressure to ship faster, reduce costs, and make better use of every square foot. That’s where Modula storage systems stand out as a modern solution for space and efficiency challenges.

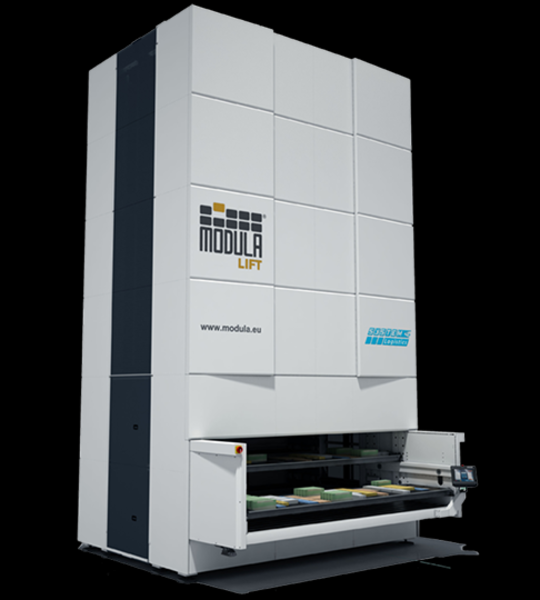

Unlike traditional racking, Modula’s automated storage systems are designed to maximize vertical space, streamline picking operations, and keep inventory secure and organized. Below, we’ll explore the four biggest benefits of Modula storage and why more businesses are choosing it as the backbone of their warehouse strategy.

1. Space Savings: Recover Up to 90% of Floor Space

Warehouses often underestimate how much wasted space they’re sitting on — particularly above head height. Traditional racking can only climb so high before it becomes unsafe or impractical.

Modula storage systems grow vertically, reaching heights up to 46 feet. This allows businesses to recover up to 90% of floor space that would otherwise be lost to wide aisles or spread-out shelving.

Before Modula: Large footprint, wide aisles, underutilized vertical cube.

After Modula: Compact footprint, maximized height, dense vertical storage.

That recovered space can then be used for additional production lines, staging areas, or simply delaying the need for costly warehouse expansions.

Even smaller facilities can benefit. For businesses renting warehouse space in high-cost metro areas, saving square footage directly reduces monthly expenses. By consolidating inventory into a Modula storage unit, many companies avoid the need for costly offsite storage.

2. Labor Efficiency: Smarter Picking With Goods-to-Person Technology

Traditional warehouses rely heavily on a person-to-goods model, where workers spend up to 60% of their time just walking aisles. This leads to inefficiency, fatigue, and errors.

With Modula’s goods-to-person technology, that model is flipped. Instead of the worker searching for inventory, the machine brings trays directly to the operator at an ergonomic access point.

Faster Picking: Pick times can be cut by up to 65%, dramatically improving throughput.

Ergonomics: No more ladders, bending, or stretching. Operators stay in a safe, comfortable position.

Accuracy: Integrated software and pick-to-light systems reduce human error, helping achieve up to 99.9% accuracy.

Consider the labor savings: if an operator spends 8 hours a day walking, searching, and picking, a Modula system can cut that time almost in half. Multiply that across an entire workforce, and the annual savings are substantial.

👉 Pairing Modula units with light-directed picking systems or AS/RS solutions enhances productivity even further.

3. Security: Protect Inventory With Access Control and Traceability

Inventory loss, theft, and misplacement cost companies millions each year. Sensitive or high-value parts — such as pharmaceuticals, aerospace components, or electronics — need an added layer of protection.

Modula storage systems offer built-in security features:

Restricted Access: Only authorized employees can retrieve items using ID badges, PIN codes, or biometric access.

Traceability: Every tray access is logged, providing full accountability and audit trails.

Reduced Loss: Items are stored behind enclosed doors, reducing the risk of damage or theft.

For industries where compliance is critical, such as healthcare or defense, Modula’s security options provide peace of mind while maintaining operational efficiency.

Some facilities also use Modula systems to control access by shift. For instance, night crews may only have access to specific trays or SKUs, while sensitive or high-value parts remain restricted. This ensures companies can secure not just their warehouse overall but also manage item-level access.

4. Flexibility: A Storage System That Adapts to Any Industry

No two warehouses are alike. Some handle thousands of small parts, while others store large, heavy items or sensitive inventory. Modula storage is designed to adapt.

Pharma & Medical: Secure, traceable storage that meets strict regulatory requirements.

Aerospace & Defense: Handles high-value, mission-critical components with precision tracking.

Electronics & Manufacturing: Organizes thousands of SKUs in compact trays for faster assembly.

Retail & E-Commerce: Rapid access to fast-moving inventory for quicker order fulfillment.

Customization is another strength. Modula systems can be configured with:

Different tray heights and load capacities.

Dividers, bins, and compartments for small parts.

Integration with warehouse automation technology.

Why Businesses Are Switching to Modula Storage

Companies that implement Modula storage often see ROI in 12–18 months thanks to the combination of space savings, labor reduction, and improved accuracy.

But ROI is only part of the picture. Facilities also report:

Higher throughput without expanding headcount.

Improved worker safety, reducing workplace injuries from ladders and lifting.

Better customer satisfaction thanks to faster, more accurate order fulfillment.

In a competitive market where speed and accuracy are everything, Modula storage helps businesses remain agile and cost-efficient.

Is Modula Storage Right for Your Facility?

If you’re struggling with limited floor space, rising labor costs, or security concerns, Modula storage could be the solution that transforms your operations. By condensing your inventory footprint, automating repetitive tasks, and protecting sensitive items, Modula systems provide long-term value that traditional racking can’t match.

For businesses considering expansion, implementing Modula can delay or even eliminate the need for costly new construction. For others, it’s about increasing throughput in an existing footprint, keeping you competitive without overextending resources.

Next Steps

📌 Explore Further:

📊 Run the Numbers: Try our ROI Calculator to see how quickly Modula storage could pay for itself in your facility.

📞 Get a Free Quote: Contact Vertical Storage USA today for a space analysis and custom proposal tailored to your warehouse needs.